Call us: +44 (0) 1202 868000

Workplace Transport and Pedestrian Safety

in Paper Mills

ZoneSafe improves health and safety in paper mills by reducing collision-risk.

Health and Safety in Paper Mills – The Risks

Unintended transport hazards in the paper manufacturing industry, particularly where pedestrians and vehicles interact, significantly increase the risk of fatal and severe injuries from accidents. This danger is often exacerbated by limited visibility in environments where the movement of large loads and machinery can severely obstruct views and clear lines of sight.

According to RIDDOR data:

- The manufacturing sector experienced 16 fatal injuries to workers in 2023/24, with a five-year average of 17 deaths per year.

- Being struck by a moving vehicle caused 25 worker fatalities across all industries in 2023/24, representing 18% of all worker deaths.

The persistent and serious nature of transport-related risks highlights the critical need for robust safety measures in manufacturing, including operations like paper mills. This is vital for protecting workers, and indeed, under health and safety law, employers have a legal duty to ensure, as far as reasonably practicable, their employees’ health, safety, and welfare.

Our pedestrian detection system actively boosts situational awareness and promotes safer practices within paper manufacturing facilities, effectively lowering the chance of collisions between vehicles and pedestrians.

We’re proud to protect workers and health and safety in paper mills, delivering a tried-and-tested proximity warning system that promotes a ‘Zero-harm’ culture. Find out exactly what our customers say about ZoneSafe in our case study videos.

*These provisional figures will be finalised in July 2025. This allows HSE to account for any necessary adjustments or late reports that may come in.

Sector Statistics up to 2023/2024*

%

Non Fatal Injuries to Workers Struck by Moving Vehicles

x

Higher Fatality Rate Than Average Across Industries

Fatal Injuries to Workers Per Year

Help your employees

to feel safe at work

Protect your

employer reputation

Improve your

safety culture

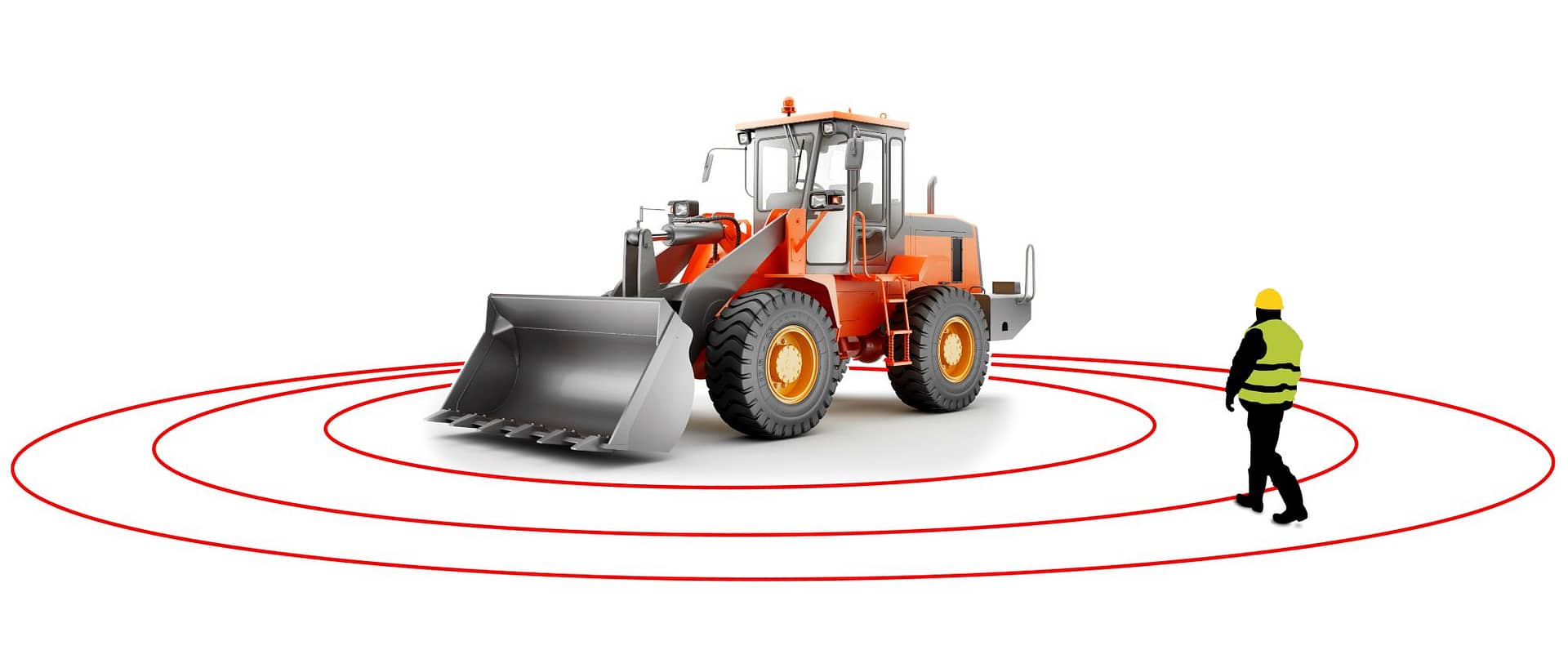

Manoeuvring Blind Spots Safely With 360° Detection

Keeping your workforce safe on busy worksites operating heavy plant machinery is no easy task. Vehicle blind spots, concealed entrances, blind corners, obstructions and unexpected behaviours all increase the risk of a pedestrian being hit by a moving vehicle.

ZoneSafe proximity warning technology excels in health and safety in paper mills. Unlike other solutions available on the market, such as an AI camera system, Zonesafe’s pedestrian detection system does not rely on line of sight, and it will detect pedestrian workers (even when they can’t be seen!) from behind walls, racking, pallets and even paper reels, thanks to its clever use of RFID technology.

ZoneSafe Vehicle-to-Person Alert works by fitting an antenna to the vehicle. This creates a 360-degree detection zone around the vehicle, helping to eliminate vehicle blind spots. Pedestrian workers wear a ZoneSafe tag, which the antenna detects every time the pedestrian (and tag) enters the detection zone. Once detected, the in-cab control unit warns the driver via an audible and visual alarm, and the tag worn by the pedestrian vibrates, alerting the pedestrian to the danger of the approaching vehicle.

Multi-Fleet

Vehicle Applications for

Health and Safety in Paper Mills

Shovel Loaders

Shovel loaders are a significant hazard to pedestrians. Large buckets, attachments, even the shape of the vehicle creates blindspots for the driver and increases the risk of collisions.

Forklifts

Forklifts have many different blind spots thanks to the loads they carry, distorted view from the cab and shape of the vehicle. These significantly increase the risk of collisions.

Health and Safety in Paper Mills

Risks from Workplace Transport

Risks from Workplace Transport

It’s essential to segregate moving vehicles and pedestrian workers on your worksite. There are many different areas and situations in paper mills where this isn’t always possible, such as any area where a vehicle reverses. Vehicle blind spots and site layout all increase the risk of accidents.

ZoneSafe works in any paper manufacturing environment, including:

-

Pulping

-

Sheet Formation

-

Environmental/Effluent Treatment

-

Woodyard/Fiber Procurement

Pedestrian Access Control

Restricting site access to only your employees or anyone given a ZoneSafe tag reduces the risk of accidents. Only ZoneSafe tags open gates or barriers to a restricted area meaning they'll be detected and warned should they get too close to a moving vehicle.

Vehicle-to-Vehicle Detection

Reduce the risk of accidents between moving vehicles with ZoneSafe vehicle detection anti-collision system. Fitting any type of vehicle, the system provides two configurable warning zones, an outer pre-warning (or early warning) zone and inner (close proximity) warning zone.

Benefits of Using Proximity Warning Systems in the Paper Manufacturing Industry

✔ Fewer workplace accidents lead to savings on medical expenses, compensation claims, and repairs to expensive equipment.

✔ Helps paper mills meet stringent health and safety regulations, avoiding potential fines and improving compliance.

✔ Reduces downtime caused by accidents and disruptions, ensuring smoother operations in high-traffic areas.

✔ Proximity warning systems prevent collisions between forklifts and workers in busy paper mills, reducing the risk of injury.

Improve Your Health and Safety in Paper Mills.

Find out what other paper manufacturing sites say about ZoneSafe

“Since implementing ZoneSafe’s proximity warning systems, our workplace safety has significantly improved. After experiencing a near-miss with forklifts and pedestrians, we knew we had to take immediate action. We’re proud to say that since adopting ZoneSafe, we’ve had no incidents or near-misses, and we’ve now extended this technology to multiple sites across Europe.”

Other Projects We’ve Delivered

Liberty Steel,

Steel Manufacturer

Steel Manufacturer

Liberty Steel implemented a safety and asset protection system designed to stop cranes from colliding.

See how ZoneSafe can provide a solution for you Get in touch