Warehouses are bustling places, and keeping the daily operation efficient is crucial to maintaining on-time order fulfilment requirements. The constantly moving environment with multiple pieces of equipment, vehicles, and pedestrians working together around the clock opens opportunities for safety incidents and equipment damage. Heavy equipment vehicles, including forklifts, pallet trucks, and lifts, are commonly used—important measures are in place to ensure the safety of heavy machinery.

Warehouse machinery equipment is critical to operations, and accidental damage can cost businesses vast amounts of money. Efforts should be made to maximise the lifespan and increase the efficiency of heavy equipment in the workplace.

Below, we look at how warehouse operators can ensure the safety of heavy machinery.

1. Regular Maintenance

As with any vehicle, regular maintenance is necessary to keep warehouse machinery equipment running safely and effectively. Well-maintained equipment is safer to use, helping to identify faults and potential risks and issues before they malfunction.

Many regular maintenance checks are legal obligations, but it’s worth considering additional checks to ensure warehouse machinery safety. Regular maintenance results in increased reliability, and fewer breakdowns can prolong the lifetime of costly equipment.

- Commit to a strict and well-planned maintenance schedule for all plant equipment and heavy machinery

- Include routine inspections to identify signs of wear and tear – consider pre-use checks and end-of-day inspections

- Keep detailed records of maintenance activities, including repairs and parts replacement, and ensure all maintenance staff are updated with training and procedures. Maintenance logs are a requirement under Provision and Use of Work Equipment Regulations 1998 (PUWER)

In addition to company- and equipment-specific maintenance checks, Thorough Examination is a requirement under health and safety law. Forklifts and lifting equipment are covered under LOLER 1998, while PUWER 1998 relates to all other safety-related items, including brakes, steering, and tyres.

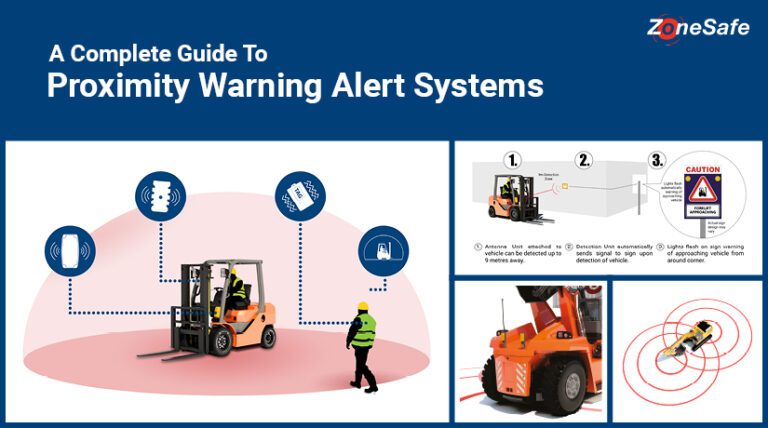

2. Invest in Proximity Warning Technology

ZoneSafe’s Vehicle Detection Anti-Collision System is a powerful addition to the heavy machinery safety toolkit. It significantly reduces the opportunity for vehicle collisions with plant machinery, other vehicles, or pedestrians.

The system delivers audio and visual alerts through alarms and flashing lights to drivers and equipment operators well in advance of a collision, therefore minimising the risk of safety breaches and accidental damage. ZoneSafe is easily applied to almost any warehouse machinery equipment, including forklifts. Forklifts are vital pieces of equipment in warehouses, enabling easy movement of heavy consignments and high manoeuvrability, but they are unfortunately involved in a staggeringly high number of serious workplace accidents every year, and their heavy weight and tendency to topple can result in devastating consequences.

Investing in safety technology has wide-ranging benefits and can cost much less than expected.

The benefits of applying a proximity warning system:

- Reduce the opportunity for vehicle and pedestrian collisions in the workplace

- Create segregation in areas where there are space limitations

- Demonstrate a strong commitment to workplace safety, raise morale and build trust within the workforce

- Take real action that helps to avoid serious accidents, downtime, and costly damage to warehouse machinery equipment and vehicles

- Address known high-risk locations, including blind spots, corners and crossings

- Collect safety-critical data to help identify unsafe behaviours, vehicle malfunctions and danger zones within the environment

3. Establish clear traffic management policies.

The Health and Safety Executive (HSE) recommends total segregation of people and vehicles where possible and separate areas for reversing. In a busy warehouse, this is often difficult to achieve due to narrow aisles and space limitations.

Robust traffic management policies must be in place to reduce the chance of vehicle accidents and damage. Some measures that can be taken include:

- Designate pathways and traffic lanes for the movement of heavy machinery

- Implement speed limits and traffic control measures such as crossing and traffic lights systems to control and slow traffic

- Enforce strict guidelines around the passage of pedestrians and other vehicles in areas where heavy equipment operates

- Regularly review and update traffic management strategies within the warehouse to ensure effectiveness

- Apply activated signage for warehouses – one of ZoneSafe’s latest solutions to effectively improve driver awareness and raise the alarm before a collision occurs

4. Monitor Environmental Conditions

Environmental factors such as dust, humidity and adverse weather conditions can have a detrimental effect on heavy machinery safety, causing blockages, corrosion or overheating, all of which can result in damage that affects performance and reduces the vehicle’s lifetime.

Controlling these conditions by incorporating sufficient ventilation and climate control can help to address dust, humidity and fumes. Sufficient lighting is essential in improving visibility and maintaining high awareness around heavy equipment so that accidental damage is less likely to occur.

5. Encourage Reporting and Feedback

Maintaining an open and honest forum for feedback and reporting is crucial to upholding a strong safety culture. Accidents happen even when robust measures are in place, and every incident should be treated as a learning opportunity.

- Create an accessible system for employees to report equipment issues or safety concerns promptly

- Encourage feedback from operators and maintenance staff regarding equipment performance, concerns and areas for improvement

- Respond promptly to reported issues and investigate the root causes

ZoneSafe works with warehouse facilities to address safety concerns around heavy machinery. ZoneSafe proximity warning solution helps to prevent pedestrian-to-vehicle and vehicle-to-vehicle collisions, ensuring a safer and more productive workplace.

Contact ZoneSafe to discuss your warehouse safety challenges today