Heavy equipment and vehicles are commonly used in the most dangerous industrial sectors including agriculture, construction, manufacturing, transport, and waste and recycling. These hazardous industries repeatedly score highest in workplace injury and fatal accident rates, and workplace vehicles play a leading role.

Every year, heavy equipment vehicles are involved in serious and fatal injuries – being struck by a moving vehicle is the second most common cause of fatal accidents in the UK. 23 people were killed by moving vehicles in 2021/22 and each year sees around 2,500 incidents where workers fall from vehicles, are struck or run over by a moving vehicle, or from vehicles overturning. Forklifts alone are involved in around a quarter of all workplace transport accidents with five workers hospitalised as a result of a lift truck accident every day. And almost 75% of ‘impact with a third person’ events involve pedestrians working on completely unrelated tasks to the truck operation.

Many worksites operate multiple types of heavy equipment like cranes, forklifts, excavators and HGVs, at the same time and in close proximity, creating more opportunities for accidents to happen. Restricted driver visibility is a common problem, especially with large loads, buckets or reversing. The weight, size and power of these heavy equipment vehicles pose a fundamental risk to people working nearby. Poor segregation is a major cause of what could otherwise be avoidable accidents.

Proximity sensors for heavy equipment:

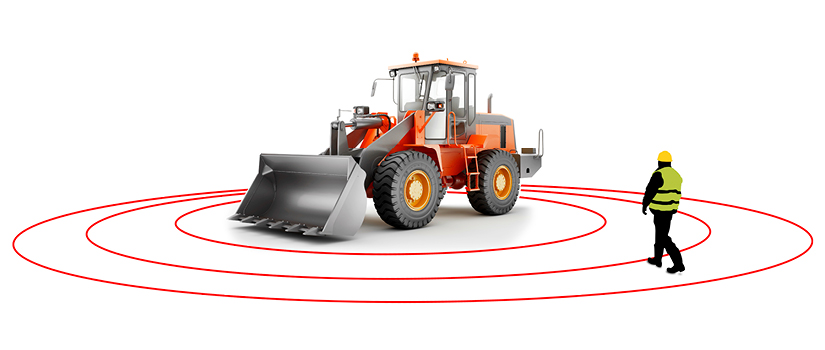

ZoneSafe Proximity Warning Sensors provide a solution by offering heavy equipment operators a safe and effective way to create segregation and mitigate risk. Proximity sensors create a detection zone around hazards, and alert operators and pedestrians before accidents happen. The system delivers a visual, audible and/or vibration warning that alerts heavy equipment operators and pedestrians when in close proximity, to take action to reduce the risk of vehicle-pedestrian collisions.

ZoneSafe proximity sensors are easily attached to heavy equipment while pedestrian workers wear small, easy to apply tags that interact directly with vehicles when entering the detection zone. By applying proximity sensors to heavy equipment, blind spots are removed and everyone operating within the area is alerted when a threat is nearby.

Benefits of proximity sensors for heavy equipment:

Improved safety and behavioural change

Segregation is possible even in confined or busy locations. Workers and equipment operators are alerted to hazards before an accident happens, making the workplace safer. When the detection zone is breached and a warning is received, workers become aware of the impending risk as alerts educate users to danger zones, increase situational awareness and drive positive behaviours around high-risk areas.

Affordable and easy to apply

ZoneSafe proximity sensors for heavy equipment are surprisingly affordable and can be adapted to suit most environments. Tags are easily applied to vehicles while pedestrians wear tags on lanyards, clothing, hard hats or in pockets as part of everyday PPE. Tags are highly accurate and strong enough to withstand harsh conditions.

Robust data

Built-in data analytics mean every breach produces valuable insights that can be used to analyse high-risk areas, activities and worker behaviour. This valuable data can then be used to enhance safety training programmes to improve overall safety knowledge and culture.

It’s impossible to eliminate all risks associated with heavy equipment but measures must be taken to reduce the chance for accidents as much as possible and segregation is often the most effective way to achieve this. ZoneSafe proximity sensors for heavy equipment make this possible in most situations.

Contact us for more information, alternatively Arrange Virtual Meeting

The Health and Safety Executive (HSE) provides valuable guidance and information around workplace transport assessment and safety on its website – Workplace Transport Guidance