On 10th June 2025, the UK Material Handling Association (UKMA) will launch its new safety initiative for National Forklift Safety Day (NFSD), with the slogan “A painted line isn’t enough.”

The campaign aims to make the material handling industry safer. It’s focused on implementing meaningful and lasting safety measures and obtaining more accurate information about accidents involving material handling equipment (MHE).

The NFSD campaign is shifting from technical guidelines to a more emotionally impactful approach. The goal is to emphasise the devastating consequences of collisions involving material handling equipment.

However, David Goss, the Technical Director of the UKMHA, has outlined, “Accidents tend to become mere statistics, but for those involved, the consequences can last a lifetime. By highlighting the human cost of such accidents—not just on the victims but also on equipment operators, co-workers, family, and friends—we aim to highlight the human story that is the reality behind every statistic.”

To align with this year’s campaign, “A painted line isn’t enough,” we’ll explore the safety challenges linked to material handling equipment and the solutions and technologies available to address them.

Pedestrian and Vehicle Segregation

Segregating vehicles and pedestrians is the best way to protect against any potential vehicle-pedestrian collision.

Painted Line Markings

Painted line markings are often used to create walkways and designated safe zones. However, this also relies on both vehicle and pedestrian staying between the lines, adhering to the rules, and not leaving their designated areas. Without safety barriers fitted, the danger of a vehicle-pedestrian collision is still high, and we couldn’t agree more with the NFSD’s slogan, “A painted line isn’t enough.”

Safety Barriers

Physical segregation, such as a safety barrier, is the best protection against potential vehicle-pedestrian collisions. It offers outright prevention, protecting your workforce from being struck by a moving vehicle. Safety barriers are usually fitted along painted line markings to significantly increase worksite safety. However, installing a safety barrier may not always be possible due to site layout and space limitations. To help prevent this problem, safety barriers are often designed into building plans for new warehouses, ensuring they work within the workspace layout.

Safety Signage

Strategically placed mandatory warning signs can help separate vehicles and pedestrians on a worksite. However, this safety method is passive, meaning it depends on everyone in the area reading the signs. Unfortunately, “sign blindness” can occur when people become too familiar with or are repeatedly exposed to these vital safety warnings, making them less effective.

When Physical Segregation Isn’t Possible

Even with existing safety measures, risks remain. Furthermore, completely separating workers from material handling equipment isn’t always feasible due to site layout or workflow. Fortunately, technologies now exist to help equipment operators and pedestrians navigate worksites safely. Some safety solutions are versatile enough for various environments, while others are best suited for specific conditions. These include both passive and active safety solutions. Let’s take a closer look at them:

Vehicle LED Safety Lights

Usually fitted to forklift trucks, these systems project a light or beam around the vehicle, often in a halo shape. This effectively marks a safe distance on the floor around the vehicle and improves vehicle visibility. The LED safety lights come in different shapes and sizes, specific to your vehicle and site requirements. This safety method works best indoors, particularly in noisy areas, because visual cues become paramount when auditory warnings are obscured or unheard in such settings. Vehicle LED safety lights don’t work as well outside because direct sunlight makes them less visible. Unlike active safety, the light system relies upon pedestrian workers’ awareness to look in the correct direction to spot the light marking, similar to a painted line. However, even with this limitation, it still provides a vital visual “last line of defence” for pedestrians.

AI Camera Systems

AI cameras represent the latest advancement in active safety technology. They give equipment operators visual confirmation of pedestrians’ location and evaluate the situation around them. More advanced AI cameras can even recognise human shapes and movements and actively alert drivers to their presence. It’s important to note that these systems typically do not warn pedestrians directly; they only warn drivers when pedestrians are nearby. Their line of sight also limits what they see. Camera systems cannot see pedestrians hidden behind objects. In busy places like warehouses, where forklifts and people work together, furniture such as shelves, pallets, or even stacks of products creates blind spots. This can make cameras less effective and often means installing multiple cameras to achieve 360-degree visibility around each vehicle.

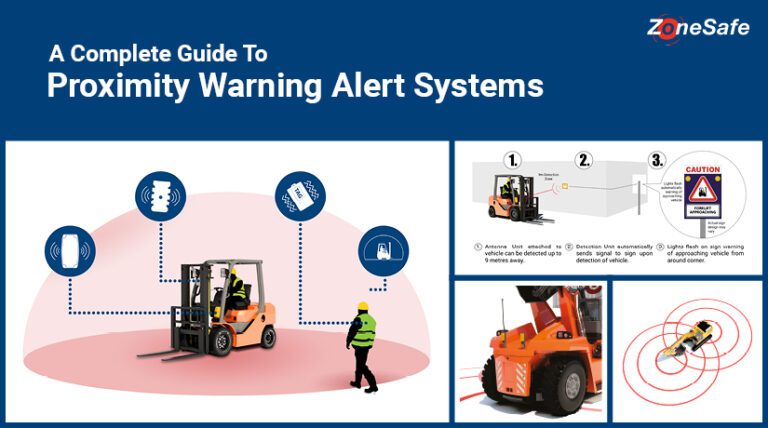

Proximity Warning Systems

Proximity warning systems are a vital safety tool designed to proactively prevent workplace collisions and reduce accidents by enhancing situational awareness through real-time alerts for both drivers and pedestrians. Site managers can customise a detection zone around forklifts (or any other type of vehicle) that triggers automatically when a pedestrian or another vehicle enters the proximity. This dual detection ensures both operators and pedestrians receive immediate visual and audible alerts when in close contact. Unlike AI camera systems, proximity warning systems typically offer 360-degree coverage from a single unit. For larger vehicles or more complex scenarios, multiple antennas can also be fitted to increase the detection zone around the vehicle and ensure complete safety. These systems leverage different technologies to achieve their safety objectives, primarily Radio-Frequency Identification (RFID) or Ultra-Wide Band (UWB).

RFID systems

RFID systems use a lower frequency range and shorter detection distance, making them suitable for detecting pedestrians. A crucial advantage of RFID is that it does not rely upon line of sight; it can effectively detect RFID tags worn by pedestrians through walls, racking, or other visual barriers. When pedestrians are detected, the driver receives an audible, visual warning from the in-cab control unit. In contrast, the pedestrian worker is made aware of the vehicle approaching through tag vibration. This is the first safety solution to offer 2-way feedback.

UWB systems

UWB systems, on the other hand, feature a much higher frequency range, enabling them to detect people or vehicles at greater distances with exceptional accuracy. It’s important to note that while precise, UWB systems work better for vehicle detection because they rely on line of sight for their extended range.

Activated Signage

Activated signage offers an innovative safety solution for warning large areas of people about the dangers of an approaching vehicle. These signs flash only when they detect moving vehicles and stop flashing once the vehicle moves away and the immediate threat is gone. This approach is ideal for areas where both workers and the public might interact with moving vehicles.

Automated Projected Signage

Unlike passive painted line markings, visual warning signal projectors provide an active safety visual alert system. These projectors constantly highlight potential danger zones by projecting bright lines or symbols on the ground. This gives pedestrian workers and other vehicle operators a clear visual warning that’s especially effective in noisy environments or areas with poor visibility. The main goal is to provide an unmistakable visual cue that boosts awareness and helps prevent collisions.

Data Collection and Analytics

Systems such as proximity warning solutions and AI camera systems aren’t just about real-time alerts; they are powerful tools for gathering valuable data. Gaining more accurate insights into near-misses, pedestrian hotspots, and behaviours is incredibly important, as this data is crucial for making informed health and safety decisions.

Meaningful, Lasting Safety Measures

The UKMHA’s latest safety initiative strongly emphasises the necessity of implementing meaningful and lasting safety measures. While technology significantly boosts our safety efforts, unwavering vigilance and adherence to strict health and safety guidelines are paramount in any workplace. These essential guidelines include:

- Adequate lighting and visibility: Ensuring all areas are well-lit and clear of obstructions.

- Comprehensive training and refresher courses: Regularly updating knowledge and skills for all personnel.

- Strict traffic management plans: Implement clear vehicle and pedestrian routes and controls.

- Consistent enforcement of safety rules: Upholding standards to ensure compliance and accountability.

- Regular reminders on seat belt use: Reinforcing this fundamental safety practice for vehicle operators.

- Mandatory utilisation of appropriate Personal Protective Equipment (PPE): Always ensure everyone on-site wears high-visibility clothing to make them easier to spot.

By understanding the strengths and limitations of each safety technology, we can implement multi-layered solutions that protect people and businesses from the devastating impact of serious safety failings.

Are you ready to start creating a safe workplace?

ZoneSafe transforms high-risk workplaces, meeting hazards head-on and taking a preventative and proactive approach to workplace safety. When you engage with us, we collaborate with you and your team to identify your specific challenges and requirements, enabling us to deliver successful project outcomes that benefit your business and operations. Our dedicated site safety experts are located across the country. They are ready to offer on-site consultations and discuss workplace challenges, helping you implement effective safety solutions that bring your worksite safety project to life. If you would like to book a live-stream video demonstration of our products, please do not hesitate to get in touch:

Get involved on social media using #NationalForkliftSafetyDay.