Die Sicherheit von Fußgängern ist bei der Arbeit mit Werkverkehr und schweren Maschinen von entscheidender Bedeutung. Jedes Jahr ereignen sich schwere und tödliche Unfälle aufgrund von Zusammenstößen zwischen Fahrzeugen und Fußgängern. Geeignete Maßnahmen zur Eindämmung dieses Risikos sind entscheidend für die Unfallvermeidung. Wenn man Lösungen für Annäherungswarnungen in Betracht zieht, ist es wichtig, den Unterschied zwischen markierungsbasierten und nicht markierungsbasierten Annäherungswarnsystemen zu verstehen. Bei der Vielzahl der verfügbaren Lösungen kann es jedoch schwierig sein, die beste Maßnahme zu finden und zu entscheiden, in welche Produkte man investieren sollte. Es ist von entscheidender Bedeutung, die richtige Lösung für Annäherungswarnungen auszuwählen, die den spezifischen Herausforderungen Ihres Arbeitsplatzes gerecht wird.

AI-Detektionskameras

KI-Erkennungskameras werden immer beliebter und bieten unter bestimmten Umständen eine gute Lösung. Sie sind besonders effektiv an Orten, an denen die Mitarbeiter nicht "markiert" werden können oder an denen der Zugang der Öffentlichkeit unkontrolliert ist. Diese Kameras nutzen fortschrittliche Technologie, um potenzielle Gefahren zu überwachen und zu erkennen.

Wie funktionieren AI-Detektionskameras?

Die Kameras nutzen die Video-Content-Analyse (VCA), um das Live-Videomaterial zu analysieren. Das System vergleicht diese Inhalte mit seiner Datenbank mit vordefinierten Bildern und löst einen Alarm aus, wenn es einen Fußgänger erkennt. Damit das System effektiv arbeiten kann, müssen die Bilder vorab in die Datenbank geladen werden und verschiedene Szenarien enthalten, wie z. B. verschiedene Personen, Hindernisse, Fahrzeuge und unterschiedliche Umgebungsbedingungen. Dadurch wird sichergestellt, dass das System potenzielle Gefahren genau erkennen und darauf reagieren kann.

KI-Erkennungskameras können zwar sehr effektiv sein, haben aber auch gewisse Einschränkungen:

Beleuchtungsbedingungen: KI-Kameras funktionieren gut in kontrollierten Umgebungen, z. B. in Fabriken mit gleichmäßiger Beleuchtung. In Außenbereichen können Kameras jedoch durch helle oder schwache Lichtverhältnisse und Witterungseinflüsse eingeschränkt werden, die die Sicht der Kameras behindern können.

Sichtlinie: AI-Detektionskameras arbeiten innerhalb ihrer direkten Sichtlinie und können keine Objekte oder Personen um Ecken, in unübersichtlichen Kurven, hinter Wänden oder Regalen erkennen. Diese Einschränkung kann in Umgebungen mit komplexen Grundrissen zu potenziellen Sicherheitsrisiken führen.

Datenbank-Abhängigkeit: Die Wirksamkeit von KI-Erkennungskameras hängt stark von der Vollständigkeit ihrer Bilddatenbank ab. Wenn die Datenbank nicht ausreichend detailliert ist, besteht das Risiko falsch positiver oder negativer Ergebnisse. So könnte die Kamera beispielsweise eine Person nicht erkennen oder ein Objekt fälschlicherweise als Fußgänger identifizieren. Außerdem können KI-Kameras in komplexeren Umgebungen, die sehr detaillierte und vielfältige Bilder erfordern, Schwierigkeiten haben.

Trotz dieser Einschränkungen erhöhen KI-Kameras die Aufmerksamkeit der Fahrer erheblich und ermöglichen es ihnen, Aktivitäten zu stoppen und Unfälle zu vermeiden.

Tag-basierte Annäherungswarnsysteme

Tag-basierte Annäherungswarnsysteme bieten einen anderen Ansatz, indem sie gleichzeitig sowohl Fahrer als auch Fußgänger warnen, wenn sie sich in unmittelbarer Nähe befinden. Dieses duale System reduziert nachweislich Kollisionen zwischen Menschen und Fahrzeugen am Arbeitsplatz. Diese bewährte Technologie hat im Laufe der Jahre die Sicherheit auf Baustellen für viele namhafte Kunden erheblich verbessert und wird dies auch weiterhin tun.

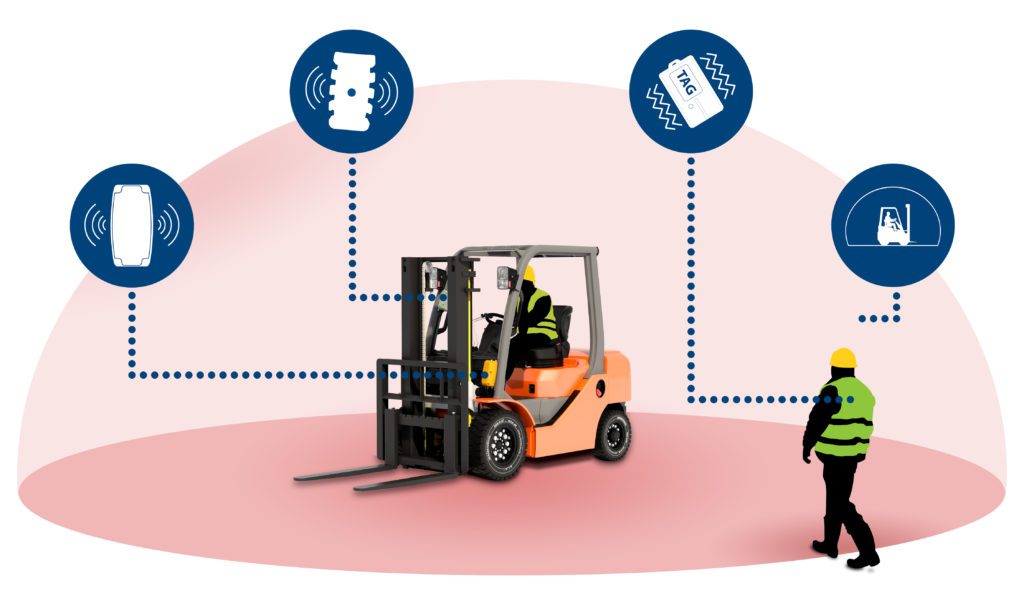

Wie funktioniert das ZoneSafe Tag-basierte System?

Das ZoneSafe-Tag-System besteht aus einer Steuereinheit in der Kabine und einer Antenne, die an jedem Industriefahrzeug, z. B. einem Gabelstapler, angebracht wird. Den Fußgängern, die in dem Bereich arbeiten oder ihn besuchen, werden kleine Tags zugewiesen. ZoneSafe nutzt die RFID-Technologie, um einen konfigurierbaren 360-Grad-Erkennungsbereich um Fahrzeuge und schwere Maschinen zu schaffen. Wenn ein markierter Fußgänger diesen Bereich betritt, löst das System einen Alarm in der Fahrzeugkabine und eine Vibration des Fußgänger-Tags aus, um beide Parteien auf die potenzielle Gefahr aufmerksam zu machen.

Die Vorteile der Verwendung von Tag-basierten Systemen - Unsichtbares sichtbar machen!

In belebten Umgebungen wie Lagerhäusern, Recyclingzentren und Fabriken ereignen sich Unfälle häufig an neuralgischen Punkten wie toten Winkeln, Ecken und Kreuzungen. Autofahrer können nicht immer sehen, was vor ihnen liegt, und Fußgänger können versehentlich in den Weg eines Fahrzeugs laufen. Tag-basierte Systeme wie ZoneSafe bieten eine zuverlässige Verteidigungslinie, indem sie sowohl den Fahrer als auch den Fußgänger auf das Vorhandensein eines Risikos hinweisen, selbst wenn die Sicht beeinträchtigt ist. Die RFID-Technologie ermöglicht es ZoneSafe, um Ecken und durch Hindernisse hindurch zu sehen". Sobald der Erkennungsbereich durchbrochen wird, werden die Arbeiter durch akustische, optische und Vibrationsalarme gewarnt, so dass sie anhalten und Kollisionen vermeiden können. Diese Tag-basierte Lösung wird häufig mit der Fahrzeugerkennung kombiniert, um eine weitere Sicherheitsebene auf der Baustelle zu gewährleisten.

Widerstandsfähig in rauen Umgebungen

Ungünstige Witterungsbedingungen und schlechte Sicht können die Risiken am Arbeitsplatz verschärfen. Staub, Rauch, schlechte Beleuchtung, starker Regen, Nebel oder andere Umweltfaktoren können zu schweren Unfällen beitragen. ZoneSafe wurde für Umgebungen mit hohem Verkehrsaufkommen und hohem Risiko entwickelt und ist so konstruiert, dass es selbst den schwierigsten Bedingungen standhält. Das System funktioniert bei allen Wetterbedingungen und ist unempfindlich gegen Staub, Rauch oder schlechte Sicht. Das robuste Gehäuse hält selbst einem Sturz aus der Höhe oder dem Überfahren mit einem Fahrzeug stand und gewährleistet eine zuverlässige Leistung.

Zugangskontrolle

Neben der Unfallvermeidung kann die ZoneSafe-Technologie auch den Zugang zu gefährlichen oder eingeschränkten Bereichen kontrollieren. Die Tags können so programmiert werden, dass sie mit Zugangskontrollschranken, Ampeln oder anderen Systemen kommunizieren, um die Einfahrt in Gefahrenzonen zu regeln. Diese Funktion erhöht die Sicherheit an unfallträchtigen Orten, indem sie steuert, wann Fahrzeuge und Personen einfahren können.

Daten-Einblicke

Während des Einsatzes sammelt ZoneSafe Daten, die in der Cloud gespeichert werden und zur Analyse einfach heruntergeladen werden können. Diese Daten geben Aufschluss über das Verhalten der Mitarbeiter, die Fahrzeugaktivität und sicherheitsrelevante Bereiche. Diese Informationen werden häufig zur Erstellung gezielter Schulungsprogramme und zur Unterstützung einer positiven Sicherheitskultur am Arbeitsplatz verwendet.

Zusätzlich zu den tagbasierten Annäherungswarnsystemen bietet ZoneSafe auch nicht tagbasierte Annäherungswarnsysteme an, die die Sicherheit am Arbeitsplatz erhöhen. Diese Systeme verwenden andere Arten von Sensoren und Technologien, um die Umgebung zu überwachen und notwendige Sicherheitsmaßnahmen auszulösen.

Nicht auf Tags basierende Annäherungswarnsysteme: Aktivierte Beschilderung und sensorgestützte Warnungen

Eines unserer nicht auf Tags basierenden Annäherungswarnsysteme ist das aktivierte Beschilderungssystem, bei dem an der Wand montierte Sensoren zur Überwachung bestimmter Zonen oder Aktivitäten eingesetzt werden. Diese Sensoren können Bewegungen oder die Anwesenheit von Fahrzeugen in Risikobereichen erkennen und automatisch blinkende Warnschilder oder Sicherheitsmechanismen auslösen, wie z. B.:

Automatische Schranken: Der Sensor kann ein sich näherndes Fahrzeug oder einen Fußgänger erkennen und das automatische Schließen oder Öffnen der Schranken auslösen. Dadurch wird sichergestellt, dass nur befugte Personen oder Fahrzeuge in Sperrbereiche eindringen, was den unbefugten Zugang verhindert und das Unfallrisiko verringert.

Optische und akustische Alarme: Wenn ein Sensor eine potenzielle Gefahr erkennt, kann er optische und akustische Alarme auslösen, um die Arbeiter vor der drohenden Gefahr zu warnen. Dies ist besonders nützlich in Bereichen mit schweren Maschinen oder eingeschränkter Sicht. Die Alarme bieten zusätzlichen Schutz, indem sie die Arbeiter auf Risiken aufmerksam machen, selbst wenn sie ein sich näherndes Fahrzeug nicht bemerken.

Kontrollierte Zugangspunkte: Sensoren können in Zugangskontrollsysteme wie Ampeln oder Schranken integriert werden, um den Verkehrsfluss in stark frequentierten Bereichen zu steuern. So kann das System beispielsweise an einer Lagerkreuzung oder einer stark befahrenen Kreuzung innerhalb einer Anlage den Zeitpunkt der Fahrzeug- und Fußgängerbewegungen steuern, um das Risiko von Zusammenstößen zu minimieren.

Die Vorteile von Näherungswarnsystemen, die nicht auf Tags basieren

Diese nicht auf Etiketten basierenden Annäherungswarnsysteme sind äußerst vielseitig und werden häufig in verschiedenen Umgebungen eingesetzt, in denen ein auf Etiketten basierendes System nicht ideal ist, oder als zusätzliche Sicherheitsebene. Einige Vorteile sind:

Flexibilität: Das aktivierte Beschilderungssystem kann an bestimmte Standorte und Sicherheitsanforderungen angepasst werden. In Bereichen, in denen es nicht möglich ist, jede einzelne Person zu kennzeichnen, kann das sensorgestützte System dennoch eine effektive Sicherheitslösung bieten.

Erhöhte Sicherheit: Durch die Automatisierung von Reaktionen auf erkannte Gefahren tragen diese Systeme dazu bei, Unfälle proaktiv zu verhindern, ohne auf menschliches Eingreifen angewiesen zu sein. Dies verringert das Risiko menschlicher Fehler und gewährleistet einheitliche Sicherheitspraktiken.

Nahtlose Integration: Nicht tagbasierte Annäherungswarnsysteme können in bestehende Sicherheitsprotokolle und -systeme integriert werden. Sie können beispielsweise mit anderen ZoneSafe-Produkten, wie z. B. markierungsbasierten Systemen, zusammenarbeiten, um ein umfassendes Sicherheitsnetzwerk innerhalb einer Einrichtung zu schaffen.

Kostengünstig: In Szenarien, in denen nur einige wenige Risikobereiche überwacht werden müssen, kann aktivierte Beschilderung eine kosteneffektive Alternative zu komplexeren Lösungen darstellen und gezielten Schutz dort bieten, wo er am meisten benötigt wird.

Anwendungen

Näherungswarnsysteme, die nicht auf Tags basieren, sind von Vorteil:

Öffentliche Bereiche: Wo die Kennzeichnung aller Fußgänger nicht möglich ist, z. B. an Besuchereingängen oder gemeinsam genutzten Flächen innerhalb einer Einrichtung.

Feste Sicherheitszonen: Bereiche, die immer wieder Gefahren bergen, wie z. B. automatisierte Tore oder Bereiche mit gefährlichen Maschinen.

Vorübergehende Baustellen: Wenn die Sicherheit regelmäßig geändert werden muss und ein flexibles System erforderlich ist.

Da ZoneSafe sowohl markierungsbasierte als auch nicht markierungsbasierte Annäherungswarnsysteme anbietet, können Sie sicher sein, dass Sie über die richtigen Werkzeuge verfügen, um die spezifischen Sicherheitsherausforderungen Ihrer Arbeitsumgebung zu bewältigen.

Schnelle Installation und lange Lebensdauer

ZoneSafe ist äußerst anpassungsfähig und lässt sich an jedem Transportmittel am Arbeitsplatz und an schweren Maschinen anbringen. Die Installation dauert nur zwei Stunden und unterbricht den Betrieb nur minimal. Nach der Installation werden die Etiketten Teil der täglichen persönlichen Schutzausrüstung (PSA), und die Einheiten in der Kabine lassen sich problemlos in die täglichen Fahrzeugkontrollen und -verfahren integrieren. Das Ladegerät lädt die Tags innerhalb von zwei Stunden vollständig auf, und die Batterie hält bis zu drei Monate im Dauerbetrieb. Es wird erwartet, dass die Tags viele Jahre halten und so zu niedrigen Lebensdauerkosten beitragen.

Nicht alle Sicherheitssysteme sind gleich, und die Wahl der richtigen Lösung hängt von den einzigartigen Herausforderungen Ihres Arbeitsumfelds ab. Unabhängig davon, ob Sie sich für markenbasierte Annäherungswarnsysteme entscheiden, die persönliche Warnungen liefern, oder für nicht markenbasierte Annäherungswarnsysteme wie aktivierte Beschilderung, ist es wichtig, die Technologie zu finden, die Ihren spezifischen Anforderungen am besten entspricht. ZoneSafe bietet eine Reihe von anpassbaren Optionen, die die Sicherheit erhöhen und Risiken reduzieren, damit Ihr Arbeitsplatz für alle sicher bleibt. Durch die sorgfältige Auswahl des richtigen Systems können Sie eine sicherere und effizientere Umgebung schaffen, die auf Ihre betrieblichen Anforderungen zugeschnitten ist.

Die Investition in ZoneSafe ist oft erschwinglicher als erwartet, wobei einige Optionen nur zwei- bis dreitausend Pfund kosten. Darüber hinaus hat sich ZoneSafe (mittlerweile in der zweiten Generation) im Laufe der Zeit bewährt, sich als zuverlässig erwiesen und einen langfristigen Wert gewährleistet.